Digital Industry

We work on the development and application of 4.0 solutions for the improvement of production processes, among which collaborative robotics, artificial vision, virtual and augmented reality, sensorization stand out and process optimization.

ROBOTICS AND MACHINE VISION

We work in the automation and robotization of operations, being collaborative robotics and human-machine interaction one of our main fields of action. For this, we design the new processes and select the necessary technologies for the control and development of the tasks.

We are experts in 2D and 3D artificial vision systems for inspection and quality control, as well as for the detection of people and objects

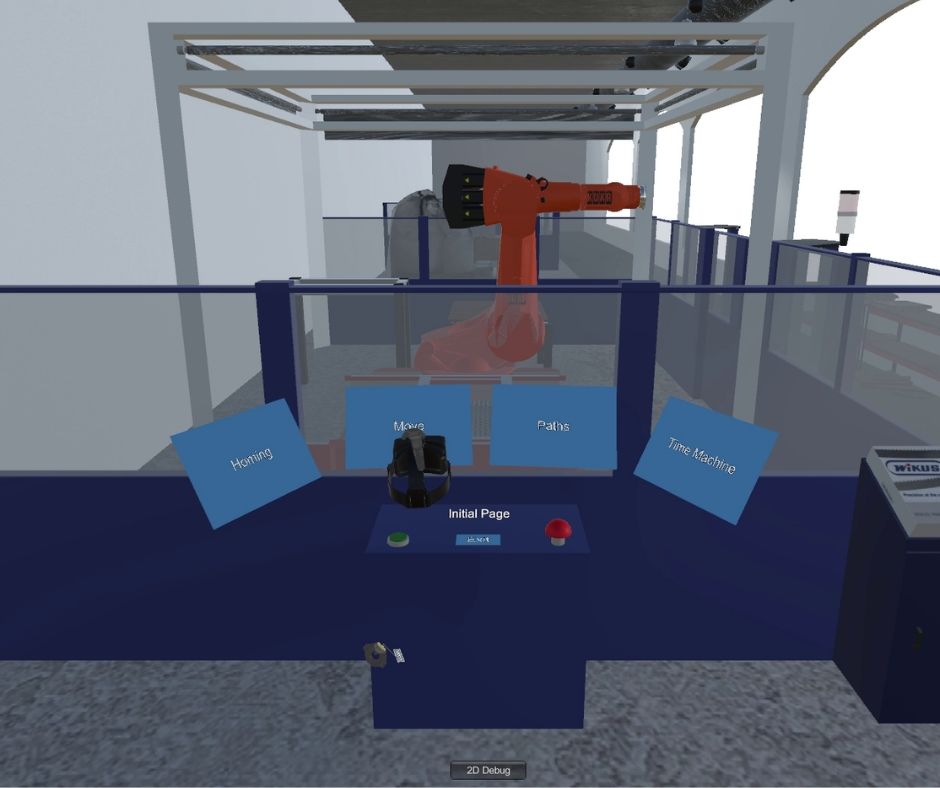

VIRTUAL AND AUGMENTED REALITY

Virtual reality is a computer simulated environment that allows user interaction in real time, creating a sense of immersion. On the other hand, augmented reality uses virtual elements on the real world, allowing interaction with an improved perception. In IDONIAL we develop:

- Virtual reality applications for training workers through immersive simulators, avoiding the use of potentially dangerous real machines and exposure to risks.

- Applications of augmented reality to improve person-machine interaction and worker assistance.

CONNECTED SYSTEMS AND ARTIFICIAL INTELLIGENCE

The increasing capacity of integration of sensory elements in devices, and the availability of communications and data networks, known as the Internet of Things (IoT), allows the incorporation of artificial intelligence for optimal and intelligent control of the processes. From IDONIAL:

- Development of data acquisition sensors

- Integration of sensors in machines and equipment to capture variables of interest that allow us to know the status of production, optimize the manufacturing process, predict behaviors...

- We carry out custom hardware and software developments for data capture and visualization, remote control, predictive maintenance, etc.

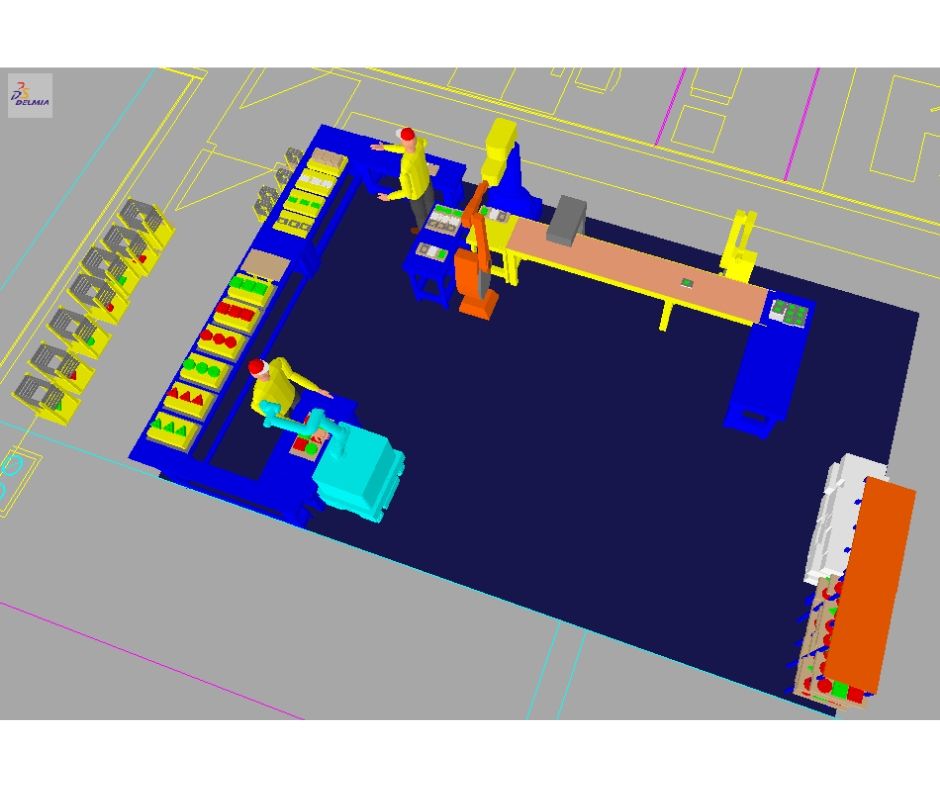

DIGITAL TWIN AND PROCESS SIMULATION

We have software tools based on the simulation of discrete events to study the behavior of a system or process in different circumstances and analyze the possible changes and their consequences before carrying them out.

Through these simulations and the analysis of the processes we can:

- Make a live digital representation of a process in different circumstances. Analyse possible changes and consequences.

- Verify the lay-out, calculate the necessary resources.

- Optimize material flows, balance production lines, stock levels, planning system...

- Analyze logistics strategies, manage queues, etc.

Following the philosophy of Lean Manufacturing, the final objective is to define an optimal configuration that allows to largely eliminate waste (operations that do not add value) associated with overproduction, waiting times, transport, process, inventories, movements, defects ...